When the accessories arrive in the warehouse, the inspector starts to check the incoming materials. At this time, the number of samples to be checked should not be too little, so as not to cause greater trouble in the production process. Inspectors will eliminate the products that do not meet the relevant technical standards and ensure that every accessory used in production is a qualified product.

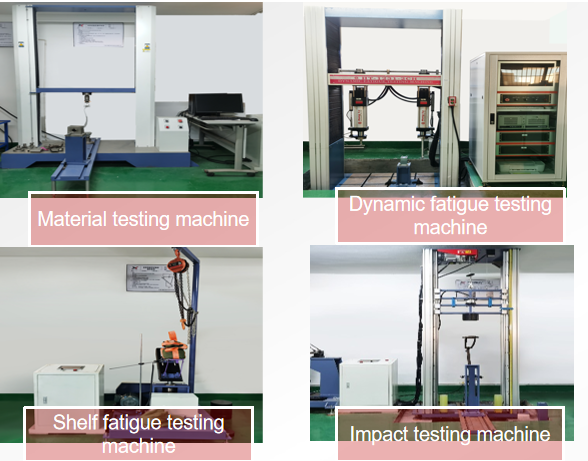

Carry out fatigue tests on the frame, including testing the frame cracking, fracture, and shock absorption function. Only after that, we start painting frames and spraying brand logos. For the sample ebike, we will test its function, performance, and appearance, and must obtain an experimental report. The factory will organize mass production when the sample ebike is qualified. During the assembly process, the bicycles will be adjusted and reworked immediately, if there are any problems.

The ebikes need to be finally inspected and tested when the assembly is completed.

Before the products are shipped, the factory will strictly inspection . We mainly check user manuals, accessories such as chargers, lighting devices, keys, and item lists, outer box labels.